Apr 07,2025

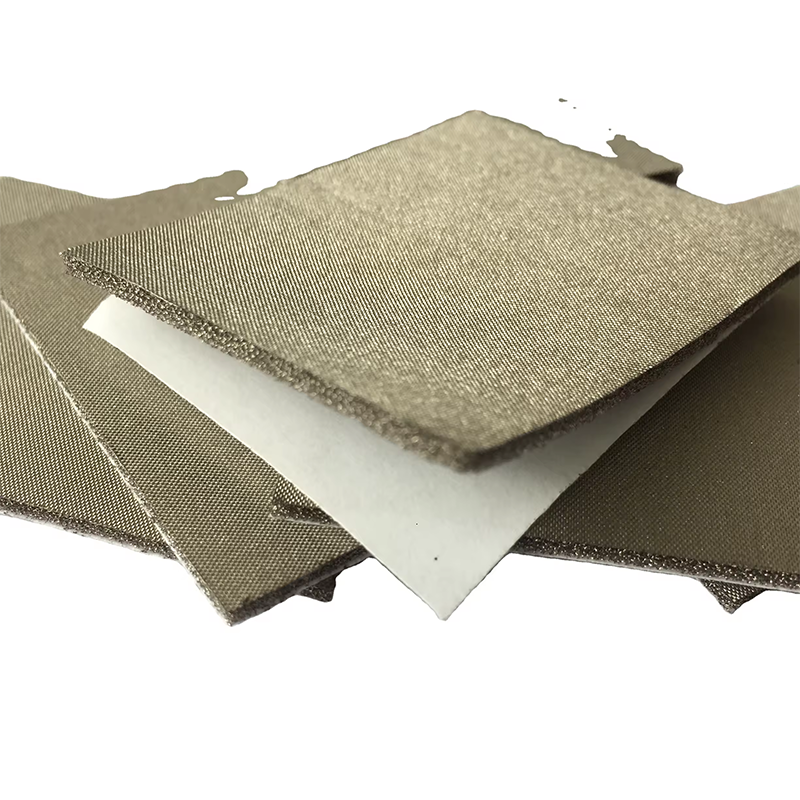

Conductive foam stands out as a special kind of material because it brings together both bounce back ability and the ability to conduct electricity, which makes it really important for protecting stuff in electronics manufacturing. What makes this foam work so well is its cell structure, which creates great barriers against those pesky electromagnetic interferences (EMI) and radio frequency problems (RFI), all without adding much weight to the product. Most often, manufacturers mix regular plastics with things like carbon particles or tiny bits of metal to get this effect. The result? A material that lasts through repeated use and performs exceptionally across different situations. Another big plus is how it soaks up impact forces, reducing damage from sudden shocks or constant vibrations. This quality becomes absolutely necessary when dealing with delicate electronic parts that can't handle rough treatment. Because of these characteristics, conductive foam plays a vital role in keeping electronic devices working properly over time.

Conductive foam works really well for EMI shielding because it can either bounce back or soak up those pesky electromagnetic signals. When manufacturers install this foam inside electronic boxes, it creates a protective layer that stops interference from getting through to delicate circuits. The way it works combines two main methods: some signals get reflected off the surface while others get absorbed into the material itself. This dual approach makes the shielding effective across different frequencies. We see these materials all over the place actually - in our everyday gadgets like laptops and phones, but especially important in things like radar systems where even small disruptions matter a lot. Without proper shielding against stray EM signals, many of our devices would just stop working reliably. That's why engineers spend so much time testing various foams to find what works best for each application.

Conductive foam is really important for EMI/RFI shielding and makes sensitive components work better and last longer. We see it used all over the place in things like smartphones, telecom equipment, and even medical gear where it protects against electromagnetic interference that could mess up operations. Take FCC Part 15 regulations as one concrete case. These rules control how much radiation electronic devices can emit, and conductive foam actually helps products pass those tests. When manufacturers build their systems with this material, they're not just following the law but also making sure their products will be accepted by customers who expect reliable performance without unexpected disruptions or failures down the road.

Conductive foam plays a vital role in protecting high precision devices from electrostatic discharge (ESD). When static builds up, this material creates a safe pathway for those charges to escape, which cuts down on the chances of damaging sensitive parts during manufacturing or regular operation. Take a look at industries where things can't afford any failures at all - think aerospace equipment, medical instruments, computer hardware. These sectors rely heavily on conductive foam because their components are so crucial to performance. What makes conductive foam really stand out is how adaptable it is. Manufacturers can shape it into different forms depending on what they need, whether its shielding delicate circuits inside satellites or preventing malfunctions in life saving medical gear. This flexibility means components stay intact longer and work better when they matter most.

Conductive foam combines both conducting and insulating characteristics, which makes it really good at improving how heat is managed in electronic devices. This material plays a big part in getting rid of the heat that builds up from all those tiny components inside gadgets. When we talk about cooling systems or protective covers for electronics, conductive foam just works better than most alternatives. Studies show that when electronics stay cool, they last longer, so using this kind of foam actually leads to better performing products over time. With companies constantly trying to squeeze more life out of their hardware while keeping things running smoothly, conductive foam keeps becoming more important in modern manufacturing practices.

AGK's conductive foam has been crafted specifically to satisfy tough fire safety requirements, which means better protection across different electronics applications. It meets those important international standards such as UL94-VO and UL94-HB, so engineers know they can rely on it even when working around potential hazards. These materials combine conductivity with fire resistance, cutting down chances of sparks catching fire inside sensitive equipment. That makes all the difference in things like industrial control panels or medical devices where nobody wants anything going up in smoke.

AGK conductive foam handles extreme temperatures really well, working reliably from as cold as -35°C all the way up to 75°C. That kind of thermal flexibility means it stands up to tough environments without breaking down. Military gear and heavy industry machinery often face wild temperature swings that would wreck standard materials, but not this foam. We've seen it maintain performance during field tests in desert heat and arctic cold alike. The material keeps doing its job consistently whether it's part of consumer gadgets or high-end industrial systems that demand rock solid performance under pressure.

AGK conductive foam was built for military applications first and foremost, able to handle whatever rough environments throw at it. The company has developed special versions that tick all the boxes for tough industries such as aerospace manufacturing and car production, meeting those exacting standards that these fields demand. Industry pros have given their thumbs up to this product time and again, which makes sense when looking at situations where things really matter. When failure isn't an option and regulations must be followed without exception, AGK foam stands out as something reliable that won't let down critical operations.

The durability factor of conductive foam really matters on those fast paced assembly lines where things are constantly moving at breakneck speeds. When parts don't wear out so quickly, it means less time spent fixing them during production runs. Research indicates that this toughness actually cuts down on overall production expenses and helps keep the assembly line running faster than traditional materials. Factory workers who have used conductive foam report that it just keeps working day after day without letting them down. One plant manager mentioned how their downtime dropped by almost 30% after switching to this material. For manufacturers looking to get more done without sacrificing quality, conductive foam stands out as a smart investment that pays off both in terms of money saved and products made.

When it comes to conductive foam solutions, customization is actually pretty smart business for manufacturers who need something specific for their applications. The flexibility here means companies can tweak these materials to fit whatever electronic specs they have without breaking the bank. Looking at industry trends shows that spending money upfront on custom conductive foam pays off over time because it just works better in the long run. Products tend to be more reliable and efficient when made this way. Electronics manufacturers face all sorts of special challenges, so being able to create exactly what's needed helps drive innovation without letting costs spiral out of control. At the end of the day, this approach delivers good quality stuff that doesn't cost an arm and a leg.

Looking ahead, sustainability remains a key driver for advancements in conductive foam tech, with many companies now exploring greener alternatives to traditional materials. There's growing interest in incorporating biodegradable elements and repurposed components into these foams to cut down on waste and pollution. This movement isn't just happening because of regulations either. Many manufacturers have started to see the business case for going green after years of pressure from consumers and investors alike. Industry insiders predict we'll see these eco-conscious approaches becoming standard practice across the board as electronics makers face mounting demands for greener products. Companies that want to stay competitive will need to find ways to balance their need for high performing materials with the reality check of reducing their environmental impact while still hitting those CSR targets set by shareholders and stakeholders.

Smart manufacturing is opening up new opportunities for integrating conductive foam materials right into IoT applications across various industries. With improvements in automated systems and better data collection methods, today's conductive foam actually responds to changes in its surroundings, making electronics work better under different conditions. This kind of flexibility really boosts both performance and dependability of electronic components over time. Looking at what's happening in the market, more companies are starting to adopt these kinds of integrated systems because they want to cut down on production costs while still improving how well their products function. We're seeing this material find its way into everything from factory equipment to consumer gadgets, showing just how transformative modern tech can be when applied properly in manufacturing settings.